As an electrician, there are certain habits you should follow to be safe. These habits include things like wearing PPE, testing your equipment before using it, and following manufacturer instructions for equipment installation. Follow these tips and become the best electrician you can be.

Table of Contents

Not Wearing PPE

The most important thing you can do to stay safe is to always wear Personal Protective Equipment (PPE). This includes safety glasses, hearing protection, hard hats, and safety shoes. These items help protect you from the hazards of electrical work by shielding your eyes from flying debris, stopping harmful noises from reaching your ears in loud environments, and protecting your head from injury, as well as preventing inadvertent contact with high voltage sources.

For example, when using power tools such as drills or saws which generate sparks, you must wear eye protection to prevent those tiny particles from damaging your eyesight long-term. The same goes for wearing ear defenders when operating noisy equipment such as circular saws or grinders.

The Centers for Disease Control and Prevention (CDC) estimates that 22 million workers are subjected to potentially hazardous noise at work each year. To protect the eardrums, OSHA advises limiting occupational noise levels below an average of 85 decibels over eight working hours.

Hard hats are another must-have item if working at a height where there is a risk of falling onto hard surfaces below, which could cause serious injury, including head trauma. They help absorb impact energy before reaching their skull, which could save lives.

Not Following Manufacturer Instructions

The best way to avoid injuries and damage is to follow the manufacturer’s instructions for equipment installation. If you don’t, you could end up with an unsafe setup that could result in serious injury or personal property damage. It happens more often than you may realize. This is why it is covered under professional liability in any insurance for electricians provided by credible organizations. If you’re working without proper insurance coverage, it’s high time you get one.

If you’re not sure how to read a wiring diagram, ask your supervisor for help. If you have any questions about what is being asked of you, ask them before doing anything. It might be possible to find another solution that works better than what is shown on paper or in the field manual provided by your employer.

Doing so will ensure that everyone has access to safe working conditions while also preventing unnecessary hazards like electrocution and electrical fire hazards caused by improper wiring methods used on equipment such as transformers.

Working With Damaged Tools

It is important to use only tools that are in good condition. If a tool is damaged or defective, it should be repaired or replaced immediately.

Before each use of a tool, you should check the tool for damage and deterioration. Damaged or worn-out parts must be replaced or repaired before the tool can be safely used again. If you don’t know how to fix the problem yourself and cannot afford professional repairs, do not operate the tool until it has been brought up to safety standards by qualified personnel who know what they are doing.

Not Checking for a Proper Ground

Electrical injuries account for around 5% of burn unit admissions in the United States. The ground is the best protection against electric shock. It prevents power from escaping and entering your body. This is what can happen when an improperly grounded electrical system shorts out and causes sparks. When you see these sparks, you know that there is a problem with the grounding of your electrical system.

Working In Unsanitary Conditions

If you work in a dusty environment, such as outdoors, it is important to wear long sleeves and gloves to avoid irritation from dust particles getting into cuts on your skin. You should also avoid inhaling large amounts of dirt/dust into your lungs through the nose when working outside during dry weather.

A team of FCI and UCL researchers, supported by Cancer Research UK, discovered a non-small cell lung cancer pathway triggered by fine particulate matter (PM2.5). These particles are 2.5 millimeters or less in diameter and are often present in vehicle exhaust and smoke from fossil fuels.

Not Testing Equipment Before Working on It

When you’re testing every piece of equipment before working on it, and after working on it, there are two things you want to look for. The first is obvious: does the equipment work? If not, then test and fix whatever’s wrong with it first.

The second is less obvious: does this piece of equipment have any safety defects? Is there something dangerous inside that could cause an electrical fire or electrocution? If so, get rid of it before using it again.

Cleaning up your workspace is one of the most important things you can do. Make sure to clean up all tools and equipment before you use them again, even if it’s just to check your work. If you’re done for the day, make sure to remove any debris from your workspace and throw it away in a proper location.

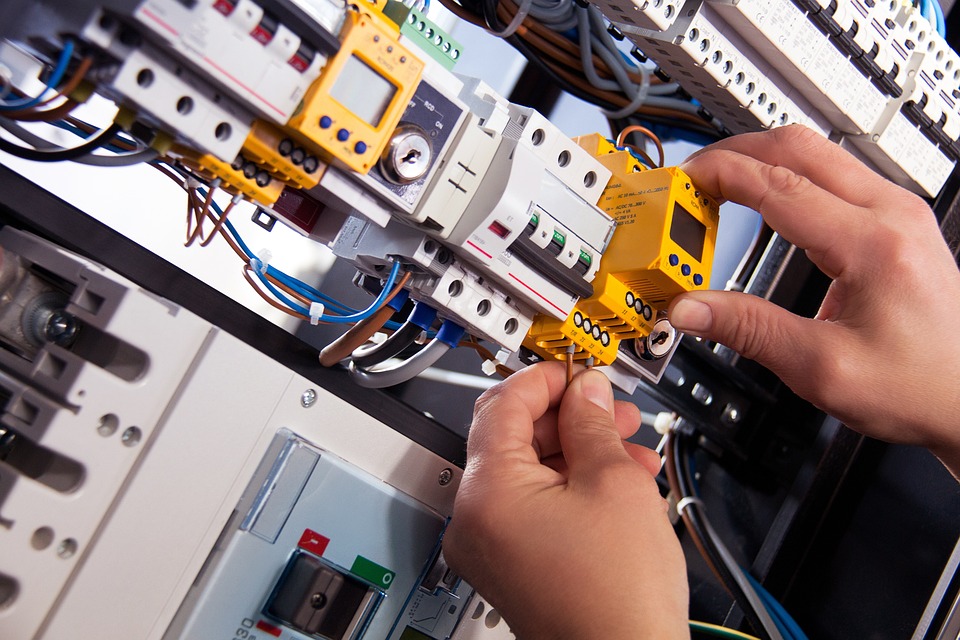

Damaging Equipment During Installation

Follow manufacturer instructions. If you’re installing a fusebox or circuit breaker, the manufacturer’s instructions will tell you how long the wires should be and how they should be routed. If they don’t specify, use common sense to determine the best way to route them to avoid damage.

Use the right tools for the job. The right tool can make all the difference when it comes time to install or repair something in your home. And using a tool that isn’t meant for a specific task may cause more damage than good.

Don’t use damaged equipment if at all possible. It’s always better to replace damaged equipment than risk electrocution with faulty wiring.

Not Following Local Codes for Wiring Installations

There are local codes in every city and state that dictate how wiring installations should be performed. These codes, which are often called electrical codes or building codes, can be found online or in books.

Knowing the local electrical code is important because it gives you a framework for understanding how to do your job safely and legally. If you don’t follow these rules, then you could end up breaking state laws and putting yourself at risk of injury or even death.

Not Using Insulated Tools

One of the most important habits to practice to be a safe electrician is using the correct tools for the job. This means using insulated tools when working on live circuits, which are any circuits that could potentially carry current. Insulated tools will prevent you from coming into contact with any current flowing through your work area, preventing injury and electrocution from occurring.

To determine if a tool has been properly insulated, you can simply check for an orange triangle somewhere on its surface. If there is no sticker or decal present, then it does not have any insulation protection.

It is important to remember that electrical work is a dangerous occupation. You need to be careful when doing your job and follow the rules, so you don’t hurt yourself or others. Wearing PPE, checking for ground faults, and cleaning up after yourself are just a few of the habits every electrician should practice.