The wire used in EDM machines is an important factor to consider when choosing the right machine for your needs. There are a few different types of wire, each with its own benefits.

In this article, we’ll break down the three most common types of wire used in EDM machines.

We’ll also discuss the individual strengths of each type, to help you decide which one is best for your needs.

So, let’s get started!

Table of Contents

The Different Types of Wire Used in EDM Machines

If you’ve ever wondered how those intricate metal designs are made, the answer is EDM machines.

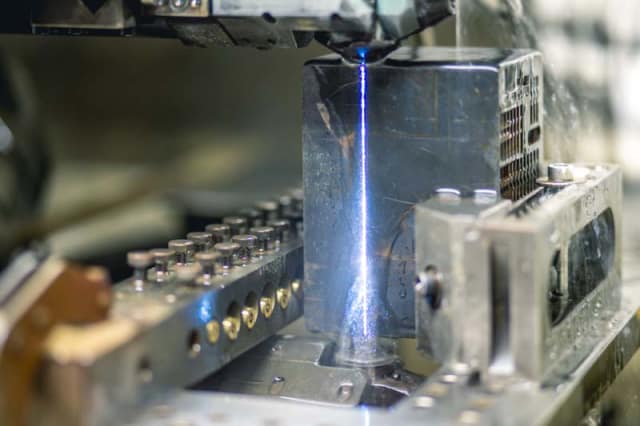

EDM, or electrical discharge machining, uses a thin wire to cut precise shapes out of metal. The wire is slowly fed through the metal, and each time it makes contact with the metal, a tiny spark is created.

These sparks erode the metal away, bit by bit, until the desired shape is achieved. The beauty of EDM is that it can create shapes that would be impossible to achieve with traditional machining methods.

Monofilament Wire

Monofilament wire is an amazing invention that has a wide range of uses, from fishing line to medical sutures. It is also very strong and durable, yet relatively inexpensive to produce.

The main component of monofilament wire is a polymer called polypropylene. This synthetic material was first developed in the 1950s and has since become one of the most widely used plastics in the world.

In addition to its strength and durability, polypropylene is also resistant to many chemicals and does not conduct electricity. These properties make it an ideal material for use in a variety of applications, including monofilament wire.

While monofilament wire may not be as well-known as other items made from polypropylene, it is an essential component of many products and plays a vital role in a wide range of industries.

Coated Wire

One of the most common uses for EDM machines is in the production of coated wire.

Coated wire is made by running a thin wire through an EDM machine that coatings the wire with a thin layer of material.

This coating can be made from a variety of materials, including metals, plastics, and ceramics. The thickness of the coating can also be varied to meet the needs of the application.

Coated wire is used in a wide range of applications, including electrical insulation,abrasion resistance, and corrosion protection.

Thanks to its versatility and durability, coated wire has become an essential component in many industries.

Wrapped Wire

One of the key components of EDM machines is wrapped wire. This wire serves as the electrode that carries the electrical current and produces the sparks. It is generally made from copper or brass, although other materials may be used in some applications.

The choice of material depends on factors such as conductivity, resistance to wear, and cost. EDM machines can be equipped with a variety of wrapped wires to accommodate different types of jobs.

As a result, wrapped wire plays an essential role in EDM operations.

Which Type of Wire is Right for You?

There are a few different types of wire used in EDM machines, and each one has its own benefits.

In this article, we’ve broken down the three most common types of wire. Now that you know more about the different types of wire used in EDM machines, you can make a more informed decision about which type is right for your needs.